Get the latest news, application notes, and upcoming webinars from XGen Bio Inc.

- About

- About XGen

- Our team

- Follow Us

- Youtube

CONTACT US

Copyright© 2025, Xgen. All rights Reserved.

Terms & Conditions | Privacy Policy | Cookie Policy

INano™ L+

Rapid Nanomedicine Preparation System

INano™ Optimux

Medium-Scale Formulation (Reusable System & GMP Compliant)

INano™ S

Commercial LNP Manufacturing System

XNano™ HT-Smart

End-to-End High-Throughput mRNA/LNP Screening Workstation

XNano™ PCV

LNP Manufacturing System For Emerging Applications

mRNA-LNP kit

Cell Transfection Kit

Application Kit

Organ-specific Targeting Kit

Validation Kit

DNA/Protein-LNP Kit

DNA-LNP Kit

Protein-LNP Kit

| This study explores the application of mixers in the preparation of lipid nanoparticles (LNPs), focusing on the effects of mixing time, particle morphology, and their impact on mRNA delivery efficiency. By optimizing mixing conditions, mRNA-loaded LNPs with similar sizes, mRNA encapsulation efficiency, and empty LNP ratios were successfully prepared using both T-junction and ring mixers. Notably, significant differences were observed in the proportion of bleb structures between LNPs prepared in the two mixers. The T-junction mixer produced a higher proportion of bleb LNPs, which was associated with a slight enhancement in mRNA integrity, while the ring mixer primarily generated spherical LNPs. In both in vitro and in vivo studies, spherical and smaller-sized LNPs exhibited higher transfection efficiency, while bleb LNPs maintained mRNA expression for a longer duration in vivo. These findings provide valuable insights for the design and optimization of mixers tailored to specific therapeutic and developmental needs. | |||||

|

|

|||||

|

Figure 1 |

|||||

02Results and Discussion |

|||||

| 2.1 LNP Preparation and Characterization | |||||

|

In this experiment, two different types of mixers—T-junction mixer and ring mixer—were used to prepare mRNA-loaded lipid nanoparticles (LNPs). First, an aqueous mRNA solution (sodium citrate buffer, pH = 4) was injected into the mixers alongside an ethanol-based lipid solution, using syringe pumps. Inside the mixer, the two solutions quickly mixed, forming LNPs. By optimizing operational conditions such as total flow rate and flow rate ratio, effective control over the LNP size, morphology, and mRNA encapsulation efficiency was achieved. To characterize the prepared LNPs, several techniques were employed. Dynamic light scattering (DLS) was used to measure the particle size distribution of the LNPs, and the results indicated that both types of mixers were capable of producing small, uniformly distributed LNPs under rapid mixing conditions. Additionally, low-temperature transmission electron microscopy (Cryo-TEM) was utilized to observe the morphology of the LNPs. Cryo-TEM images clearly revealed the spherical structure of the LNPs, as well as the presence of bleb structures on some LNP surfaces. |

|||||

|

|

|||||

|

Figure 2: Schematic of Mixing Structures A - ring mixer B - T-junction mixer |

|||||

|

|

|||||

|

Figure 3: Evaluation of Mixing Efficiency under Different Conditions |

|||||

|

2.2 Impact of Mixing Time on LNP Formation |

|||||

|

Mixing time is one of the key factors affecting LNP formation. To assess the impact of mixing time on the LNP preparation process, the Damköhler number (Da) was calculated, which represents the ratio of mixing time (t_m) to characteristic aggregation time (t_agg). When Da < 1, it indicates a rapid mixing state, where the mixing process has less influence on nanoparticle formation. Experimental results showed that as the total flow rate increased in both mixers, the Damköhler number gradually decreased and eventually stabilized, indicating that the mixing performance was sufficient to meet the requirements for LNP preparation. By comparing the relationship between the micro-mixing time (t_m) and the Reynolds number (Re) for the two types of mixers, it was found that the T-junction mixer exhibited higher mixing efficiency at higher Reynolds numbers. This suggests that, when operating in the rapid mixing region, the T-junction mixer can more effectively achieve uniform mixing of the two solutions, facilitating the formation of smaller and more uniform LNPs. |

|||||

|

|

|||||

|

Figure 4: Physicochemical Properties of LNPs Prepared under Different Flow Rate Conditions for Different Mixing Structures |

|||||

| 2.3 LNP Morphology and Structure | |||||

|

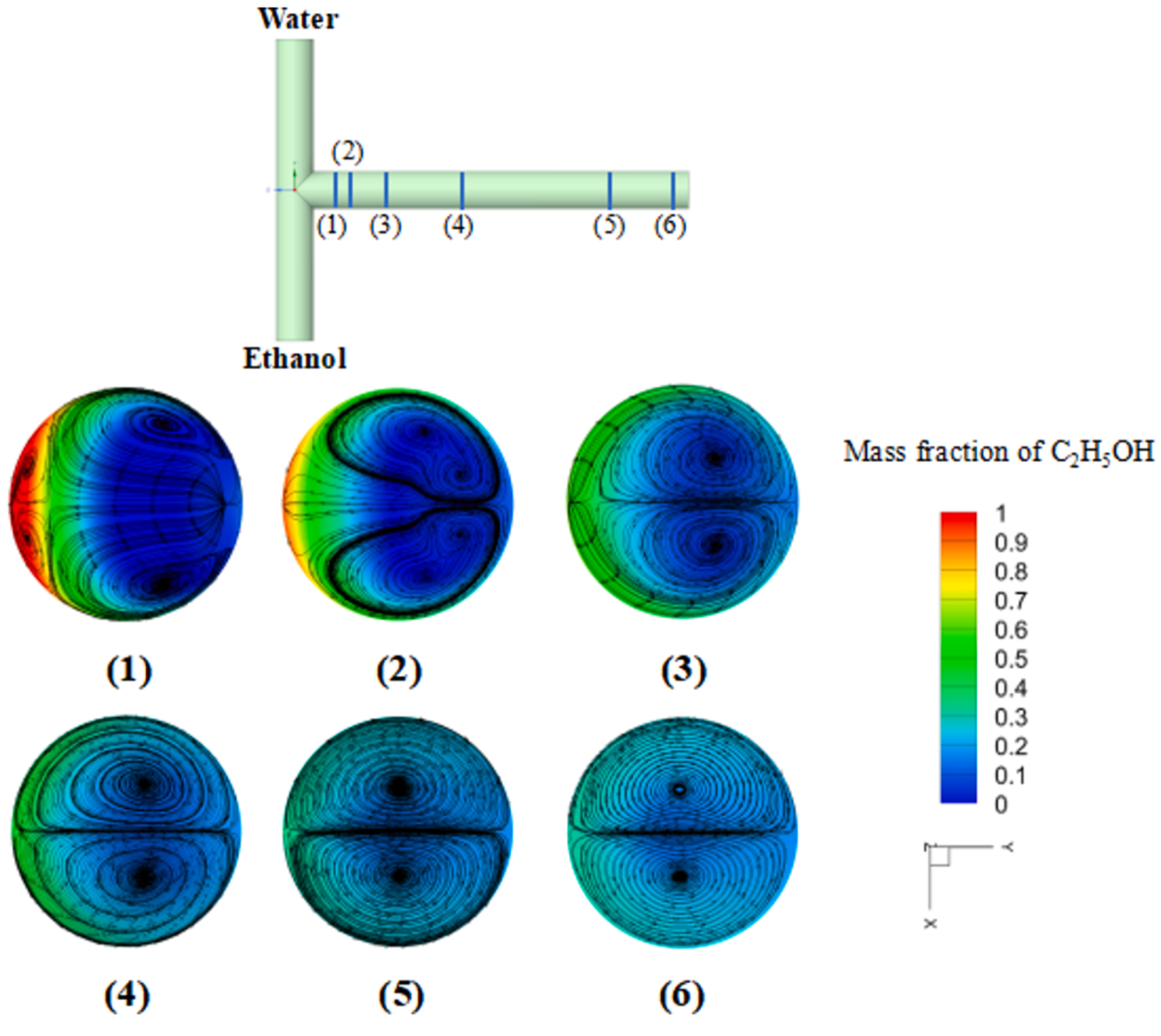

Further investigations revealed significant differences in the morphology of LNPs prepared by the two mixers. Specifically, LNPs prepared using the ring mixer exhibited a higher prevalence of bleb structures, while LNPs produced in the T-junction mixer were generally smoother with a higher degree of sphericity. This morphological difference is likely related to the geometric structures of the mixers and the fluid dynamics effects during the mixing process. To better understand the mechanism of LNP formation, the preparation process was examined in detail. The results indicated that after the rapid mixing of the mRNA aqueous solution and ethanol-based lipid solution within the mixer, an initial LNP core was formed. During the subsequent dilution process, lipids and mRNA continued to migrate, ultimately leading to the formation of LNPs with bleb structures. This finding provides important insights into the morphological evolution of LNPs. |

|||||

|

|||||

|

Figure 5: Mixing Simulation of T-junction mixer |

|||||

|

|

|||||

|

Figure 6: Structural Characterization of LNPs Prepared by Different Mixing Structures |

|||||

|

|

|||||

|

Figure 7: Mixing Simulation of ring mixer |

|||||

|

2.4 mRNA Delivery Efficiency |

|||||

|

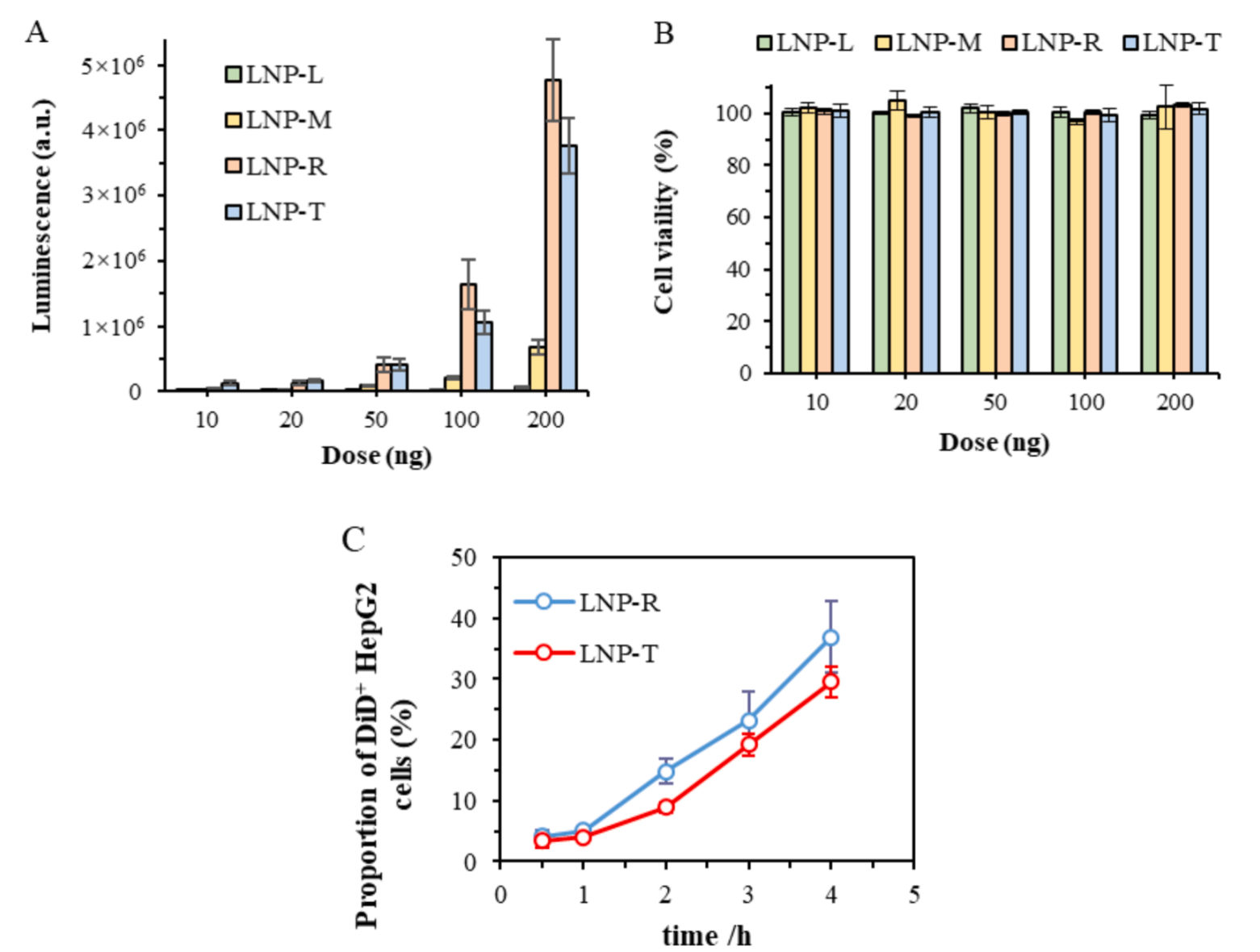

To evaluate the mRNA delivery efficiency of LNPs with different characteristics, four representative LNPs were selected for cell transfection experiments. The results showed that, despite differences in preparation conditions and microchannel geometries, the mRNA encapsulation efficiency of these LNPs was similar. However, during the cell uptake experiments, it was observed that LNPs prepared using the T-junction mixer (LNP-T) were taken up more slowly by HepG2 cells compared to those prepared using the ring mixer (LNP-R). This suggests that the morphology of the LNPs may influence their cellular uptake efficiency.

Further analysis revealed that LNP-R exhibited higher sphericity and fewer bleb structures, which may facilitate easier recognition and uptake by cells. Additionally, LNP-R showed higher in vitro transfection efficiency, especially at lower doses. These findings indicate that optimizing the morphology of LNPs can further improve their mRNA delivery efficiency. |

|||||

|

|||||

|

Figure 8: In Vitro Cellular Characterization of Different |

|||||

|

|

|||||

|

Figure 9: In Vivo Cellular Expression Characterization of Different Samples |

|||||

03

|

|||||

|

This study systematically explored the preparation process of mRNA-loaded LNPs in T-junction and ring mixers, evaluating the impact of mixing time and particle morphology on mRNA delivery efficiency. The results indicated that by optimizing mixer design, operational conditions, and formulation choices, it is possible to fine-tune mRNA delivery systems for a balance between rapid onset and sustained expression, providing strong support for specific therapeutic applications. Future research will further investigate the precise relationship between LNP structure and biological performance, as well as how mixer technology can be leveraged for more precise control and optimization. |

|||||

| Reference: Chen D., Liu Z., Guo, L., et al. (2025). Controlled preparation of lipid nanoparticles in mixers: Mixing time, morphology and mRNA delivery. Chemical Engineering Journal, 505, 159318. [DOI: 10.1016/j.cej.2025.159318]

|

|||||