Get the latest news, application notes, and upcoming webinars from XGen Bio Inc.

- About

- About XGen

- Our team

- Follow Us

- Youtube

CONTACT US

Copyright© 2025, Xgen. All rights Reserved.

Terms & Conditions | Privacy Policy | Cookie Policy

INano™ L+

Rapid Nanomedicine Preparation System

INano™ Optimux

Medium-Scale Formulation (Reusable System & GMP Compliant)

INano™ S

Commercial LNP Manufacturing System

XNano™ HT-Smart

End-to-End High-Throughput mRNA/LNP Screening Workstation

XNano™ PCV

LNP Manufacturing System For Emerging Applications

mRNA-LNP kit

Cell Transfection Kit

Application Kit

Organ-specific Targeting Kit

Validation Kit

DNA/Protein-LNP Kit

DNA-LNP Kit

Protein-LNP Kit

INano™ S

Commercial LNP Manufacturing System

Request a Quote Get Brochure

INanoTM S is a GMP-compliant commercial-scale production equipment that integrates upstream and downstream processes, including LNP encapsulation and TFF. This instrument has been successfully utilized for commercial-scale production of COVID vaccines, demonstrating its reliability and efficiency in meeting high-demand manufacturing requirements.

Flowrate range: 1-4 L/min (without dilution)

Designed with the QbD (Quality by Design) concept, allowing full adjustability of key process parameters

Compatible with public utilities such as water-for-injection and high-temperature steam for CIP/SIP, with a robust design to minimize contamination risks

Offers flexibility to use microfluidic mixing chips or T-mix mixers without the need for additional consumables.

Proven success in multiple commercial-scale production for LNPs.

|

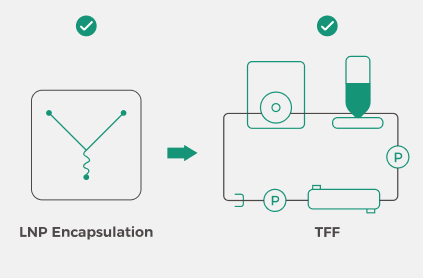

Integration of LNP Encapsulation and Downstream Processing

The Inano™ S is large-scale commercial GMP production equipment. It innovatively integrates LNP encapsulation with downstream TFF purification and concentration processes, achieving full process continuity and automation. |

|

|

|

Multiple Mixing Methods

As a platform-based device, the INano™ S not only supports microfluidic mixer and T-mixer structures, but also allows for the customization of mixing structures based on customer requirements. Additionally, it offers a variety of mixer materials for users to choose from, such as 316L stainless steel, Hastelloy, and more. |

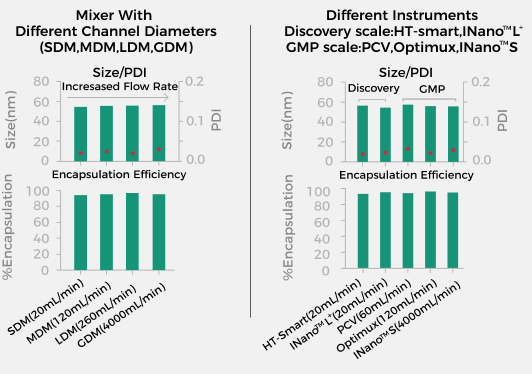

Ensure that all preparation process parameters remain unchanged to avoid secondary process development, guaranteeing a high success rate for scale-up, allowing you to easily become a process expert! |

|

|

GMP Complicance

The equipment is meticulously designed and manufactured to comply with GMP, cGMP, and EudraLex regulations. Adherence to ASME and BPE standards ensures precision and quality throughout the process. Constructed with premium materials and components, the equipment delivers exceptional stability and reliability, meeting the highest industry standards. |

|

|

|

Comprehensive Documentation and Full Traceability

The equipment's operating system is designed in strict compliance with FDA 21 CFR Part 11, incorporating multi-level user access management, data recording, audit trails, electronic signatures, and may more additional features. |