Get the latest news, application notes, and upcoming webinars from XGen Bio Inc.

- About

- About XGen

- Our team

- Follow Us

- Youtube

CONTACT US

Copyright© 2025, Xgen. All rights Reserved.

Terms & Conditions | Privacy Policy | Cookie Policy

INano™ L+

Rapid Nanomedicine Preparation System

INano™ Optimux

Medium-Scale Formulation (Reusable System & GMP Compliant)

INano™ S

Commercial LNP Manufacturing System

XNano™ HT-Smart

End-to-End High-Throughput mRNA/LNP Screening Workstation

XNano™ PCV

LNP Manufacturing System For Emerging Applications

mRNA-LNP kit

Cell Transfection Kit

Application Kit

Organ-specific Targeting Kit

Validation Kit

DNA/Protein-LNP Kit

DNA-LNP Kit

Protein-LNP Kit

XNano™ HT-Smart

End-to-End High-Throughput mRNA/LNP Screening Workstation

Request a Quote Get Brochure

The INano™ HT-Smart system enables full-process, high-throughput formulation automation, from automatic lipid mixing to the automated purification of mRNA-LNP final products. It meets the high-throughput in vivo and in vitro screening needs for large-scale cationic lipid screening, lipid formulation optimization, mRNA sequence screening, and LNP preparation process optimization.

Preparation of the 96-lipid mix: < 30 min

Synthesis of 96-LNP formulations: < 3 hours

Single-Formulation Preparation Volume: ≥ 300 uL

Unique and fully automated in-line dialysis process, enabling true end-to-end high-throughput screening

Reusable microfluidic mixer or T-mixer

Seamlessly integrates with subsequent scale-up production platforms

Built-in algorithms with 'one-click' smart operation for ease of use

|

A “True” High-Throughput LNP/mRNA Screening System INanoTM HT-Smart seamlessly integrates four core functions: ionizable lipid screening, lipid composition optimization, mRNA sequence screening, and LNP formulation process exploration.

Additionally, It features workflows for automated lipid mix preparation, and downstream buffer exchange, providing researchers with a comprehensive, all-in-one high-throughput screening solution. |

|

|

|

|

Maximize Your Freedom With a Range of Mixing Structures As a platform device, the INano™ HT-Smart supports various types of mixing structures, including microfluidic mixers, T-mixers, and other customized mixers, maximizing flexibility. |

|

|

|

|

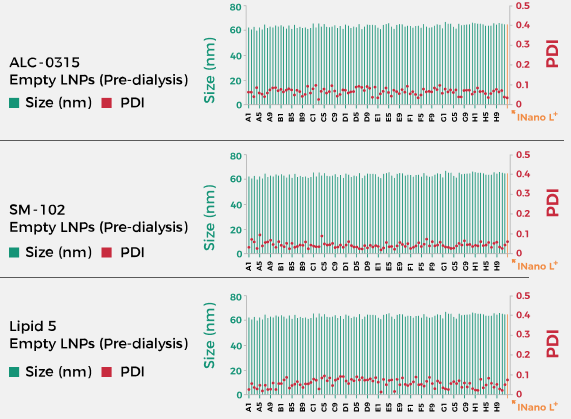

High Batch-to-Batch Reproducibility INano™ HT-Smart adopts advanced automated microfluidic technology, enabling efficient production of various formulations. Results from empty LNPs show high batch-to-batch reproducibility, with outcomes closely matching those from INano L+ (scale-up). |

||

|

|

|

Efficient and Low-Cost

Compared to traditional microfluidic preparation devices, INano™ HT-Smart offers lower operational costs and reduced time investment, enabling significant savings in R&D expenses. |

|

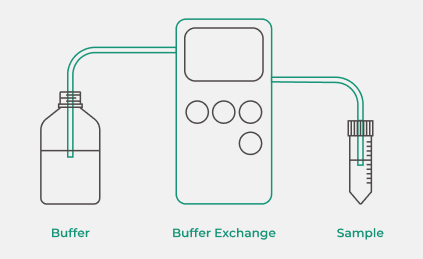

Fully Automated In-Line Buffer Exchange System

Thanks to the innovative patented design of INano's fully automated buffer exchange system, users can perform in-line buffer exchange on 96 samples, with a process that is fully adjustable to meet their needs. |

|

|

|

High Scale-Up Consistency

INano™ HT-Smart supports a minimum single sample preparation volume of 300 μL, significantly reducing material consumption during early formulation exploration stages. The formulations screened can be scaled up with consistent results on both INano™ and XNano™ devices, providing an efficient and cost-effective solution for the R&D process. |

|

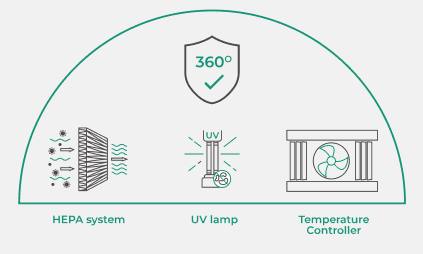

360° Comprehensive Protection

The INano™ HT-Smart features an efficient air filtration system, a temperature control module, and a UV sterilization module to effectively mitigate issues such as mRNA degradation, lipid precipitation, and endotoxin contamination. With customizable cleaning processes between sample batches, it ensures reliable and consistent experimental results allowing you to focus entirely on your experimental design. |

|

|

|

Error-Proof One-Click Operation

The INanoTM HT-Smart is equipped with validated, industry-recognized formulation algorithms, eliminating the need for complex inputs. Simply enter your desired parameters, and with one click, initiate an efficient experimental process without the risk of human error. |